Disaster Recovery Planning in the Supply Chain - an AI problem?

Oct 18, 2022 | Jagannath Rajagopal | 3 min read

On March 17, 2000, a factory fire at a Philips Microchip plant affected two companies simultaneously - Nokia and Ericsson. Ericsson adopted a reactive approach - they wanted to wait out the crisis and eat the cost of lost sales. Nokia on the other hand scrambled their supply chain; they quickly moved to tie up spare capacity at other Phillips plants and any supplier they could find. In the end, this almost bankrupted Ericsson with lost sales of $400 million; they had to merge with Sony to survive. Nokia on the other hand capitalized on Ericsson's weakness and cemented itself as #1 in cell phones.

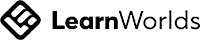

More recently, during the 2020 Covid-19 outbreak, many American restaurants and grocery outlets found themselves facing a severe meat shortage. Due to rising infections amongst minimum wage workers - who typically constitute the workforce in a meat factory, plants were being shut down to prevent spread of infection. In the meanwhile, millions of meat animals were being slaughtered and discarded; it was more economical to get rid of them, than to hold onto them for when the meat factories would open back up. A critical link in the supply chain - the factory - was broken and this threw the entire chain into the air.

Disaster Recovery requires many organizations that are only loosely connected to communicate and coordinate their activities effectively before, during and after a crisis. In order to do this, there need to be common points of reference so that everyone is speaking the same language. Further, each party related to or affected by the disaster has a different level of impact, and a varied set of needs for the recovery.

One common objective/theme of disaster recovery plans (DRP) is to minimize loss by identifying, prioritizing and safeguarding assets considered most valuable by organizations. DRPs also focus on ensuring speedy restoration of services for critical processes in the event of operational failures due to the disaster.

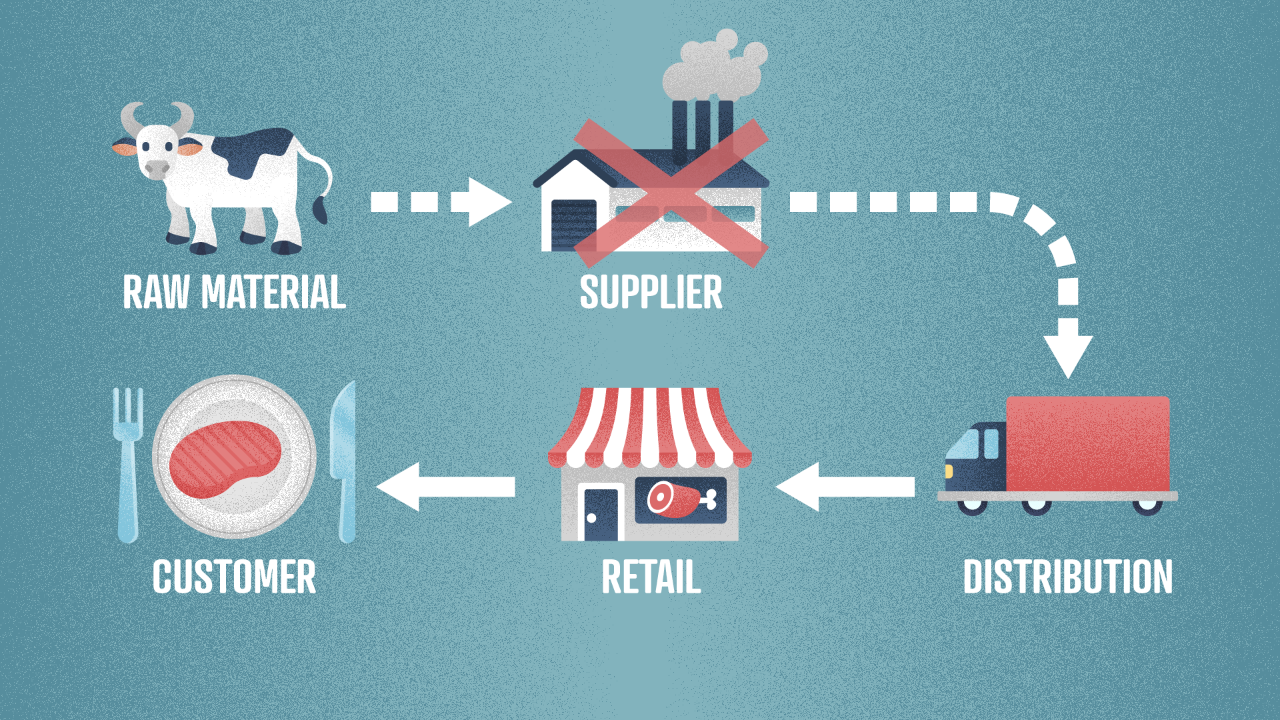

DRPs may be evaluated for different quality measures - feasibility, completeness, consistency, reliability etc. By formalizing points of reference, an ontology drives consistency to a DRP. With formal definitions, all parties speak the same language. An ontology can also model an organization by capturing its processes, organizations, people, systems, products, inventories, suppliers, business partners etc. Sometimes, it is not always possible to plan for every contingency; after the fire, Nokia actually re-designed their phones quickly to use chips from Japanese manufacturers. Capturing detailed information about the extended supply chain network can render the process of disaster recovery more complete, feasible and reliable.

I've created a LOT of resources on topics like these. Here's my course on Design Thinking for Hero Methods. Here's my YouTube channel with previews of course videos. Here's my website; navigate through the courses to find free previews & pdfs.

- - -

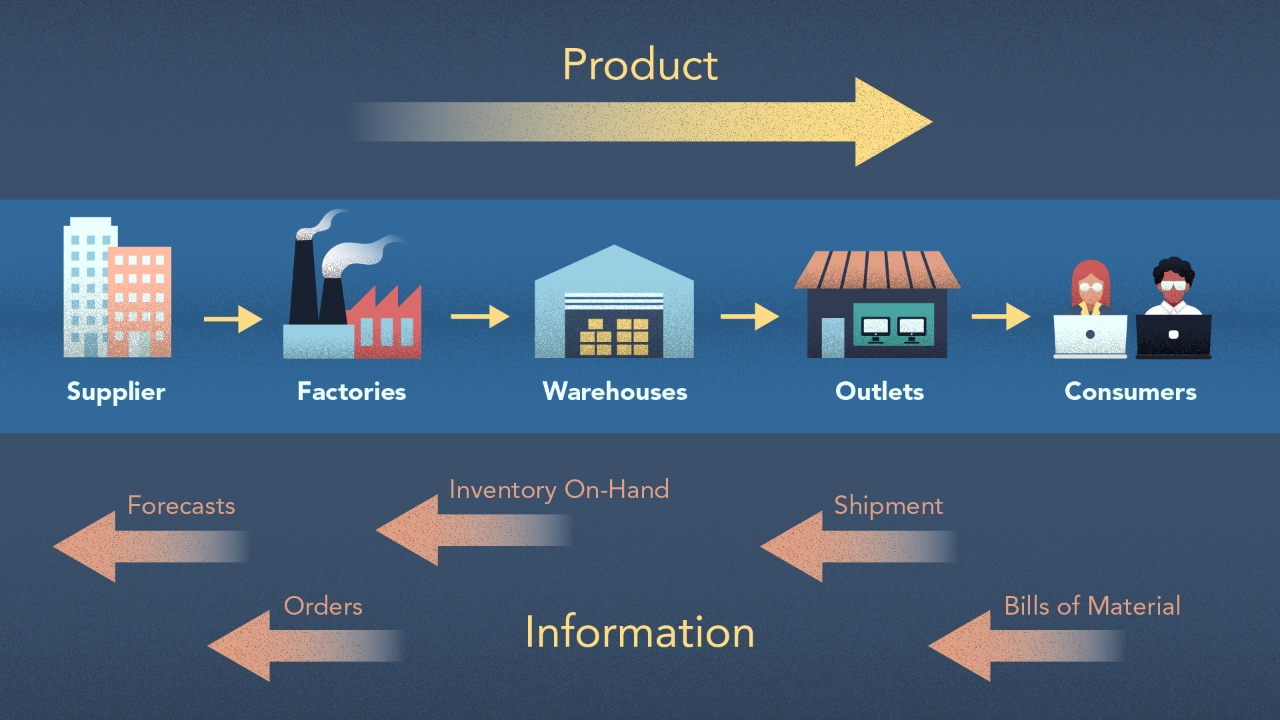

So what is an ontology? It is a description - like a formal specification of a program - of the concepts and relationships that can exist for a topic, a domain or body of knowledge. While ontologies have been seen in the field of logical reasoning for decades, they have special meaning to ACM since they can be used to define real world meaning to a computational system. An intelligent system needs to understand its world; an ontology allows its world to be understood by defining the things, concepts and ideas that make up that world, and their underlying relationships. In this sense, an ontology may also be seen as a knowledge base (KB).

Using an ontology as the main construct of a DRP system is a good idea. It enables you to form connections between types of information. Forming a logical representation of a domain - like an electronics supply chain - and keeping it up to date with the most current information - ideally in real time (though Supply Chain purists would settle for the prior day) - enables one to logically reason through scenarios in a DRP, should the worst happen. This would enable a company to better and quicker respond to events and systemic risks.

At Kado, we believe that Ontologies and advanced forms of knowledge representation are a basic building block for AI.

This is how we see the world

Machine Learning is King, but of narrow territory. Hero Methods do things that ML cannot. Taken together, not only do they help solve complex problems, they also lay the doorway to AI.

Get in touch

-

Milton, ON L9T 6T2, Canada

-

help@kado.ai

-

+1 416 619 0517

Copyright © 2026

Super!

An email is on it's way.

Super!

An email is on it's way.